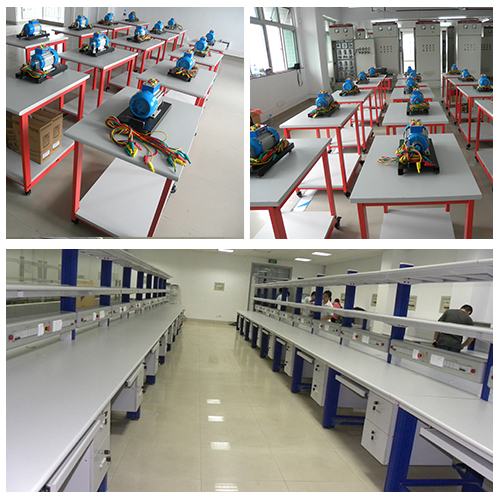

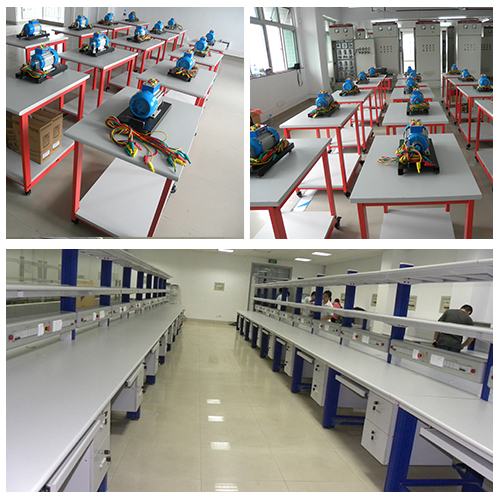

MR130M Pneumatics Discovery Bench Pneumatic Trainer Kit Educational Equipment

1. Product Introduction

1.1 Product Description

The MR130M workbench is a workbench for exploring industrial pneumatics and electro-pneumatics. It is integrated on the console and controlled by buttons and switches, electric and pneumatic, indicator lights.

1.2 Product Features

Visualization of sensor status, and FRL power modules (pressure regulating filters, booster valves) for distributors, actuators and sensors representing widely used industrial technologies.

2. Technical Specifications

2.1 Technical Parameters

Power supply parameters: AC 220V single phase ±10%

2.2 Dimensions and weight

Dimensions: 800mm×410mm×800mm

Weight: about 20kg

3. Product component names and function introduction

3.1 Product main part

No Name

1 Travel valve

2 Inductive sensor

3 Double-acting cylinder

4 Vacuum generator

5 Vacuum suction cup

6 Barometer

7 Single-acting cylinder

8 Air pump switch

9 Emergency stop button

10 Air pump switch indicator light

11 Indicator light H1

12 Indicator light H2

13 Two-position three-way single air control valve

14 Two-position five-way single air control valve

15 Two-position five-way double air control valve

16 Button

17 Output module

18 Two-position three-way single electric control solenoid valve

19 Two-position five-way double electric control solenoid valve

20 Two-position five-way single electric control solenoid valve

21 Self-reset button valve 1 (left row)

22 Self-reset button valve 2 (left row)

23 Knob-type air control valve (left row)

24 Two-position five-way self-reset button valve (right row)

25 Two-position three-way self-reset button valve (right row)

26 Two-position five-way knob-type air control valve (right row)

27 Multi-pipeline air exhaust

28 Two-way joint

29 Air compressor and air pump oil-free machine 550W-8L

3.2 Product accessories

No Name

1 European power cord, two holes, shaped tail

2 Air compressor, oil-free air pump, 550W-8L

3 European plug

4 4mm safety connection cable, 1 meter, double ends, red

5 4mm safety connection cable, 1 meter, double ends, black

6 4mm safety connection cable, 1 meter, double ends, green

7 Trachea RPU4*2.5, transparent

8 Trachea scissors TK-3

9 Trachea plug ∮4 APP4, black

10 T-type three-way RPE4 connector

11 Straight connector PU4

12 Pneumatic straight connector

4.Product Configuration List

No Name Qty

1 European power cord, two holes, shaped tail 1

2 Air compressor, oil-free air pump, 550W-8L 1

3 European plug 1

4 4mm safety connection cable, 1m, double ends, red 10

5 4mm safety connection cable, 1m, double ends, black 10

6 4mm safety connection cable, 1m, double ends, green 10

7 Trachea RPU4*2.5, transparent 30m

8 Trachea scissors TK-3 1

9 Trachea plug ∮4 APP4, black 5

10 T-type three-way RPE4 connector 3

11 Straight connector PU4 3

12 Pneumatic straight-through connector 1

13 Stroke valve 1

14 Inductive sensor 1

15 Double-acting cylinder 1

16 Vacuum generator 1

17 Vacuum suction cup 1

18 Barometer 1

19 Single-acting cylinder 1

20 Air pump switch 1

21 Emergency stop button 1

22 Air pump switch indicator light 1

23 Indicator light H1 1

24 Indicator light H2 1

25 Two-position three-way single air control valve 1

26 Two-position five-way single air control valve 1

27 Two-position five-way double air control valve 1

28 Button 3

29 Output module 1

30 Two-position three-way single electric control solenoid valve 1

31 Two-position five-way double electric control solenoid valve 1

32 Two-position five-way single electric control solenoid valve 1

33 Self-reset button valve 1 (left row) 1

34 Self-reset button valve 2 (left row) 1

35 Knob-type air control valve (left row) 1

36 Two-position five-way self-reset button valve 1

37 Two-position three-way self-reset button valve 1

38 Two-position five-way knob-type air control valve 1

39 Multi-pipeline air exhaust 1

40 Two-way joint 1

41 Air compressor air pump oil-free machine 550W-8L 1

5. Product teaching experiment list (see the experimental instructions for details)

(1) Stroke valve test experiment

(2) Vacuum suction cup test experiment

(3) Inductive sensor test experiment

(4) Pressure gauge test experiment

(5) Single-acting cylinder test experiment

(6) Two-position five-way dual air-controlled valve experiment

(7) Two-position five-way dual electric-controlled solenoid valve experiment