MR024R Compressor Training System Teaching Equipment Compressor Trainer

1 Product overview

1.1 Profile

Compressor is a kind of moving fluid machinery which elevates low pressure gas to high pressure gas, and is the heart of refrigeration system. It from the suction suction low temperature low pressure refrigerant gas, through the motor run a piston to compress, the exhaust pipes of high temperature and high pressure refrigerant gas, provide power for refrigeration cycle. So you can realize compression→ condensing(heat release)→expansion→ evaporation (absorption of heat ) refrigeration cycle. The training device through the relevant experiment, can be familiar with the use of the compressor, master the principle and control mode, the corresponding knowledge and skills, suits, higher vocational colleges, secondary vocational schools and vocational school related professional teaching and skills training examination.

1.2 Feature

1.2 Feature

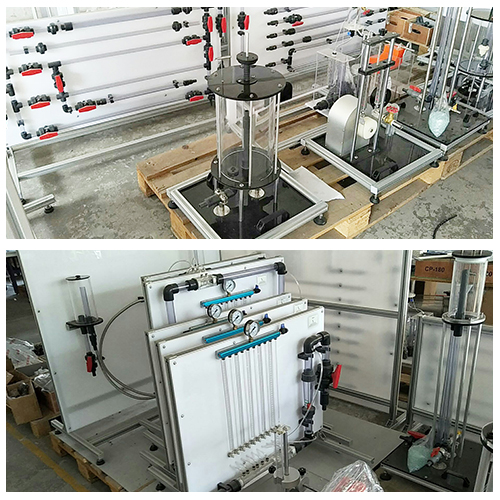

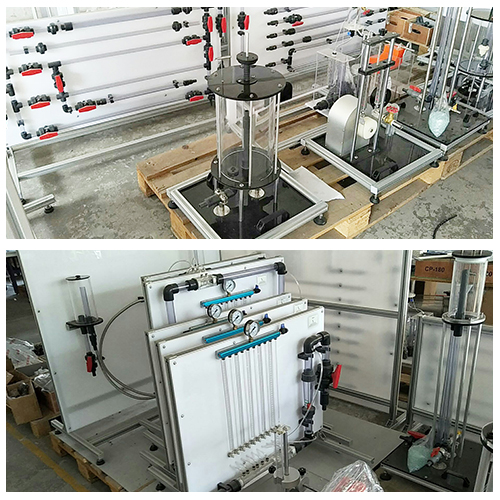

(1) Compressor training system adopts aluminum profile frame structure with light weight, strong structure and beautiful appearance. The practical training elements are installed on the panel, easy to use and not easy to damage.

(2) Compressor training system has a good safety protection system.

2 Capacity

2 Capacity

(1) input power: AC220V/50Hz.

(2) external dimensions: 670mm×340mm×650mm

(3) machine capacity: < 1KVA.

(4) weight: < 50kg.

(5) working conditions: temperature - 10 ℃ ~ + 40 ℃

relative humidity < 85% (25 ℃)+40℃

3 Product composition

3 Product composition

3.1 Compressor

Use the refrigerator special piston compressor L72CZ1.

Note: the compressor should not be tilted or inverted while storing the transportation or installation, while avoiding impact.

The compressor work with horizontal tilt is not more than 5 °.

The compressor is filled with the best amount of special frozen oil, and shall not be poured or added at will.

In order to ensure the system balance, the operation time of the compressor shall not be less than 4 minutes.

The compressor can’t be operated under high pressure or under vacuum condition.

Compressor working environment temperature not higher than 43 ℃.

3.2 Holder

3.2 Holder

Aluminum material profile support, light weight, strong structure, beautiful and generous.

3.3 Control panel configuration

(1) AC220V power supply safety output terminal is controlled by the leakage circuit breaker.

(2) Equip with start indicator light and the start button.

(3) Equip with the heavy hammer starter (electric current starter), PTC thermistor starter, overload protector, start capacitor, and run capacitance.

4.Experiments list

4.Experiments list

(1) compressor winding measurement experiment

(2) heavy hammer start mode, compressor running experiment;

(3) heavy hammer starter, capacitor start mode, compressor running experiment;

(4) heavy hammer starter, capacitor start - capacitor operation mode, compressor running experiment;

(5) PTC thermistor startup mode, compressor running experiment;

(6) PTC thermistor, capacitance starting mode, compressor running experiment;

(7) PTC thermistor, capacitance start - capacitor operation mode, compressor running experiment;