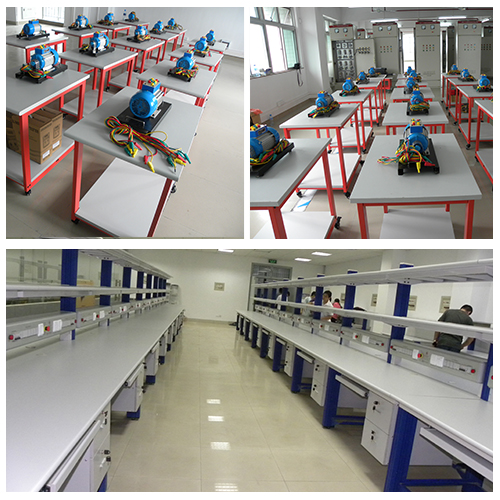

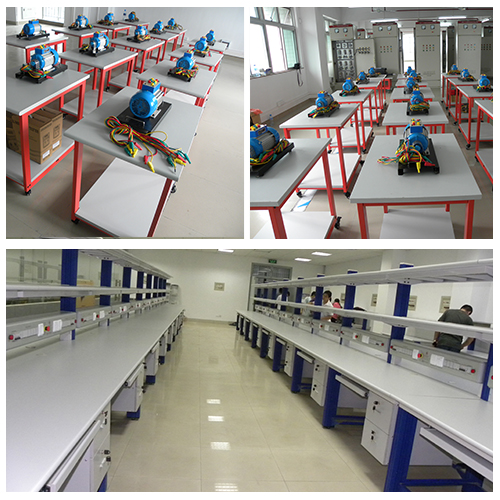

MR094M Multifunction Process Control Teaching System Process Control Trainer Vocational Training Equipment

I. Product Overview

1.1 Overview

With the improvement of people's material living standards and the increasingly fierce market competition, the quality and function of the product have also developed to a higher grade. The process of manufacturing products has become more and more complicated. The tasks of controlling the process control as an important branch of industrial automation are also heavier.

In modern industrial control, process control technology is a long -distance branch. It was applied in the 1930s. Since the development of the process control technology, the development period has been experienced in control methods from manual control to automatic control. During the automatic control period, the process control system has gone through four development stages. They are: decentralized control phase, centralized control phase, distribution control phase and on -site bus control system stage. For decades, the industrial process control has achieved amazing development. Whether in the large -scale structural complex industrial production process, or in the transformation of traditional industrial process, process control technology has played a very good process of improving product quality and saving energy. Important role.

In order to better train students in related vocational colleges, we have designed and produced the MR014M multi -functional process control teaching system. The equipment has a variety of control process experiments and can meet basic experiments.

1.2 Features

(1) The product has excellent safety, and it is specifically manifested in the protection of electrical ground reliability and the protection of heating elements.

(2) The product adopts integrated and modular design. The equipment is not only small and the functional partitions are clear, making the experimental principles more clear and making learning easier.

(3) The product adopts excellent manufacturing materials, which can extend the service life and maintenance cycle of the equipment to the greatest extent.

(4) The product has a variety of experimental modules, which greatly enriches the diversity of experiments.

II. Performance Parameters

Input power supply: single phase AC110V 50 ~ 60Hz

Size: 1050mm*480mm*800mm

Weight: <45kg

Work conditions: ambient temperature -10 ℃ ~+40 ℃; relative humidity <85%(25 ℃)

III. Components List and Detailed Introduction

3.1 Main part

Number Name

1 Stirring motor

2 Experimental container

3 Floating ball water level meter

4 PH measurement meter

5 Heater

6 TDS measuring meter

7 Mixer

8 Temperature Sensor

9 Water inlet of experimental containers

10 Drainage of the experimental container

11 Salt solution supply pump

12 Alkaline solution supply pump

13 Acid solution supply pump

14 Salt solution storage bucket

15 Alkaline solution storage bucket

16 Acid solution storage bucket

17 Electrical control panel

18 Drainage control valve

19 Water inlet control valve

20 Electric/pneumatic ratio valve

21 Pressure gauge

22 Frame body support foot

3.2 Electrical Parts

No. Name

1 2P with a leakage protector's circuit breaker

2 Power Indicator

3 TDS display instrument and measurement interface

4 PH display instrument and measurement interface

5 Power interface and control switch

6 Emergency button

7 Multi -power output interface

8 NaAh current indicator table

9 Temperature value display instrument

10 Water leveler and heating rod power output interface

11 The mixer output power supply and measurement interface

12 The supply pump power interface of acid \ alkali \ salt solution

3.3 Equipment configuration list

No. Name Quantity

Component 1 Mixer 1

Component 2 Floating ball water level meter 1

Component 3 PH measurement meter 1

Component 4 Heater 1

Component 5 TDS measuring meter 1

Component 6 Temperature Sensor 1

Component 7 Solution supply pump 3

Component 8 Control valve 2

Component 9 Electric/pneumatic proportional adjustment valve 1

Component 10 Pressure gauge 1

Component 11 Solid storage barrel 3

Component 12 2P with a leakage protector's circuit breaker 1

Component 13 TDS display instrument 1

Component 14 PH display instrument 1

Component 15 Emergency button 1

Component 16 NaAh current indicator table 1

Component 17 Temperature value display instrument 1

3.4 Accessories

No. Name Quantity

Component 1 Power cable 1

Component 2 Red 2mm electrical cable 12

Component 3 Black 2mm electrical cable 18

Component 4 4mm electrical cable 4

Component 5 PH calculation liquid 3

Component 6 Transparent water pipe 1

Component 7 Pipe clip 4

3.5 Introduction to components

IV. Experimental List

Experiment 1 Demonstrate Multifunctional Process Control Teaching System's Electric Performance Vallean Control Experiment

Experiment 2 Demonstrate multi -functional process control teaching system pH measurement experiment

Experiment 3 Using multi -functional process control teaching system to study the factors that affect the change of pH value

Experiment 4 Demonstrate multi -functional process control teaching system TDS measurement experiment

Experimental 5 Using multi -functional process control teaching system to study factors that affect changes in TDS values

Experimental 6 Use Siemens PLC to use multi -functional processes to control the pH automatic matching experiment of the teaching system