MR003P Siemens Network Communication Control Training Kit Process Control Trainer School Laboratory Equipment Educational

I.Product Overview

1.1 Overview

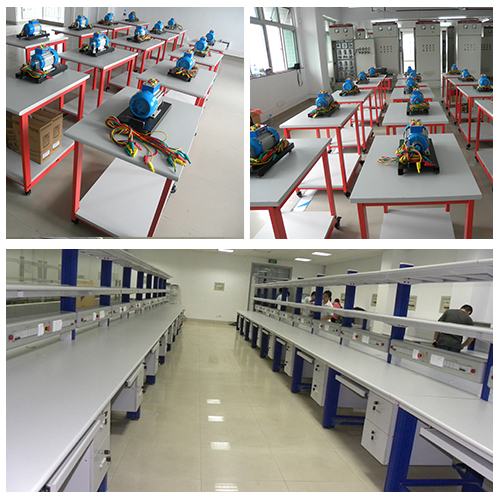

The Siemens network communication control training kit contains two parts: the actuator unit and the console.

Actuator: It is built with an aluminum alloy frame, including a water tank, a water pump, a pneumatic proportional valve, a heater, a flow sensor, a temperature sensor, a pressure sensor, etc., which can realize cascade control and PID control;

The console is also an aluminum alloy frame, including a power box, a computer, a PLC, a communication module, etc., which can hold a double-layer module hanging box unit. The PLC module wiring uses K4 terminals to transfer to the hanging box panel.

System Overview of the Siemens Network Communication Control Training Kit:

1. The system host computer uses the configuration software to monitor data and remotely control. The PLC adopts the Siemens brand, with an S7-1513+DP as the master module and an S7-1214+DP as the slave module. The master and slave stations support DP and Ethernet communication.

2. The water pump of the actuator is controlled by Siemens G120 inverter. The inverter can adjust the speed of the water pump in real time according to the analog output signal or communication method of PLC, so as to achieve the purpose of controlling the flow.

3. The instruments and sensors of the actuator are connected to PLC-S7-1214 through DP/PA coupler and AFD for communication.

4. The actuator is equipped with 2 pressure sensors and temperature sensors supporting DP protocol, which can provide ring network communication, multi-point communication and point-to-point communication

5. The actuator is equipped with 2 pressure sensors and temperature sensors supporting PA protocol, which can provide ring network communication, multi-point communication and point-to-point communication

6. The actuator is equipped with 2 pressure sensors and temperature sensors of HART protocol, which can provide ring network communication, multi-point communication and point-to-point communication

7. Configure a remote button hanging box with Siemens remote I/O module inside, and realize remote start and stop control of the equipment through Ethernet communication.

II.Performance Parameter

2.1 Technical Parameters

Power supply parameters: three-phase five-wire 380V

Siemens G120 inverter parameters: 6SL3210-1PE11-8UL1 Input: 3*400-480V, output: 0-input voltage

Siemens PLC Siemens 1214C DC/DC/DC (6ES7 214-1AG40-0XB0)

Siemens 6ES7 511-1CK01-0AB0 PLC CPU 1511C-1 PN DI16/DQ16, AI5/AQ2

RS485 signal board CB1241 6ES7 241-1CH30-1XB0

Siemens PLC analog expansion module 6ES7 232-4HB32-0XB0 SM 1232 AQ 2 x 14 bits

Siemens DP module CM1542-5 6GK7 542-5DX00-0XE0

2.2 Dimensions and Weight

Size 1: Length 2130mm Width 752mm Height 2055mm

Weight 1:<427kg

Size 2: 1705mm Width 703mm Height 1736mm

Weight 2:<234kg

III.Components List and Detailed Introduction

3.1 Main Part

Number Name

1 SLM-001301 inverter module

2 SLM-001302 S7-1200 PLC module

3 SLM-001303 S7-1500 PLC module

4 SLM-001304 DC relay module

5 SLM-001305 module

6 SLM-001311 module

7 SLM-001310 button module

8 SLM-001309 module

9 AC 220V socket

10 Three-phase power terminal

11 DC24V terminal

12 4P air switch

13 Emergency stop button

14 SLM-001308 Hart module

15 SLM-001306 touch screen module

16 SLM-001307 thermostat module

3.2 Electrical Part

Number Name

1 Experimental water tank 1

2 Temperature meter

3 SLM-001404 Ethernet remote module

4 SLM-001401 DP remote module

5 Stainless steel bucket

6 Pressure meter

7 SLM-001403 distributor module

8 SLM-001402 DP/PA coupler module

9 Emergency stop button

10 Proportional valve

11 Water pump

12 Single-phase water pump

13 Stainless steel water tank

14 Temperature meter

15 Experimental water tank 2

16 Pressure meter

17 Temperature meter

18 Pressure meter

19 Radiator

3.3 Accessories

No. Name Unit QYT

1 USB-nimi cable Aimoxun 2m 1

2 MPI download cable 1

3 USB cable 1.5m 1

4 4mm electrical cable 1m double head red 40

5 4mm electrical cable 1m double head green 20

6 4mm electrical cable 1m double head yellow 20

7 4mm electrical cable 1m double head black 40

8 4mm electrical cable 1m double head blue 10

9 4mm electrical cable 1m double head dual color 20

10 4mm electrical cable 2m double head black 10

11 4mm electrical cable 2m double head red 10

12 4mm electrical cable 4m 1

13 Three-phase motor cable (shielded) 1.2m 1

14 DP communication cable single (purple) 5 heads 1

15 DP communication cable series (purple) 1m 3

16 Network cable 1.2m 1

17 Network cable 2m 5

18 Network cable 3m 1

19 PA communication cable (green) 1m 1

20 PA communication cable (green) 2m 2

21 Air pump Set 1

22 Fuse tube 5A/5*20 10

23 DB9 communication cable 1

24 U disk Piece 1

25 Magnetic rod Piece 3

IV.Product Configuration List

No. Name QYT

1 SIEMENS G120 inverter 1 set

2 SIEMENS S7-1200 1 set

3 SIEMENS S7-1500 1 set

4 SIEMENS SIMATIC AFD4 1 set

5 SIEMENS SIMATIC ET 200SP 2 sets

6 Conjunto de HMI SIEMENS SIMATIC 1

Conjunto de 7 SIEMENS SIMATIC FDC-157 1

V.Lista de experiências

1. Experiência de controlo de temperatura PID do aquecedor

2. Experiência de controlo PID do nível da bomba de água

3. Experiência de controlo PID da pressão da bomba de água

4. Experiência de controlo PID do caudal proporcional da válvula