MR-ZT17 Heat Exchanger Service Unit Educational Equipment Vocational Training Thermal Laboratory Equipment

I. Product content

1. Product Overview

1.1 Overview

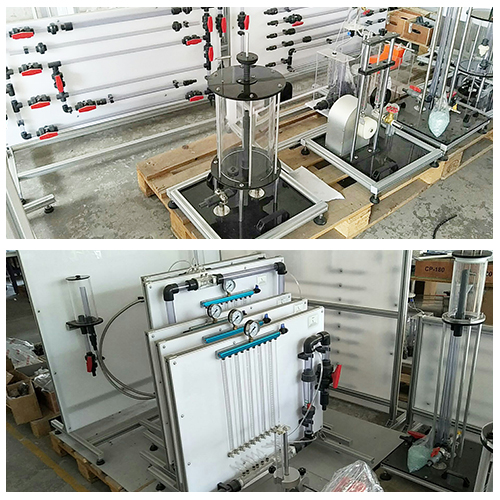

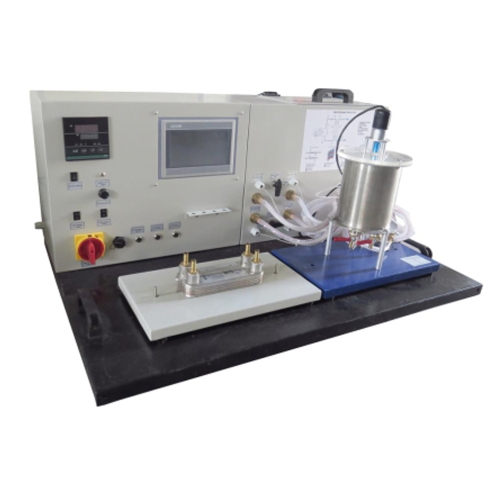

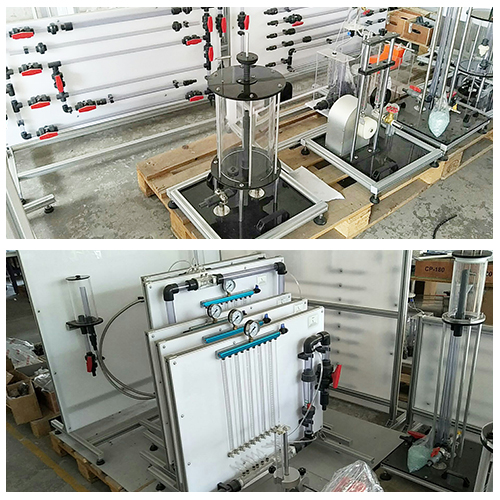

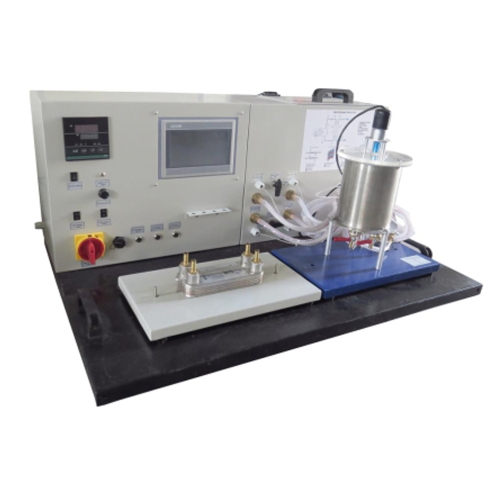

A heat exchanger is a device that transfers heat energy from one medium to another through heat exchange. Efficient heat transfer is an important research field for engineering applications. The MR-ZT17 heat exchanger test bench is a training and teaching device for the laboratory to design heat exchange capabilities for different forms of heat exchangers. The whole experimental platform uses water as the heat exchange medium, including a heat exchanger supply and control unit, a plate heat exchanger, and a tank heat exchanger with agitator and coil. During the experiment, the heat exchanger to be studied is connected to MR-ZT17. When the hot water flows through the heat exchanger, part of the heat energy is transferred to the cold water. The flow direction of the water in the circulation is adjustable. It is used to test different heat exchange methods such as forward flow and reverse flow. . MR-ZT17 provides the hot and cold water circuits required for the experiment.

1.2 Features

①The MR-ZT17 test bench has an adjustable loop flow pattern, which is used to test the heat exchange process under different flow patterns;

②The water temperature and circulating water flow rate in the circulation loop of the test bench can be smoothly adjusted;

③The plate heat exchanger and tube heat exchanger adopt modular design, which is convenient for comparison and research;

④The experimental module hot water circuit has two different layouts to study the influence of hot water flow on the heat exchange process;

⑤The experimental module of the tank heat exchanger is integrated with a stirring device to enhance heat exchange, and can also be used as an experimental control group to observe the influence of stirring behavior on the heat exchange process;

⑥The transient data during the change of the workbench is directly displayed on the display in digital form;

⑦The various physical quantity data of the workbench change process can be transmitted to the PC through the USB interface for further processing;

2. Can complete the experiment content

2.1 Analysis of the heat exchange process of the plate heat exchanger

2.2 Analysis of the heat exchange process of the tank heat exchanger with flow form a

2.3 Analysis of the heat exchange process of the tank heat exchanger with flow pattern b