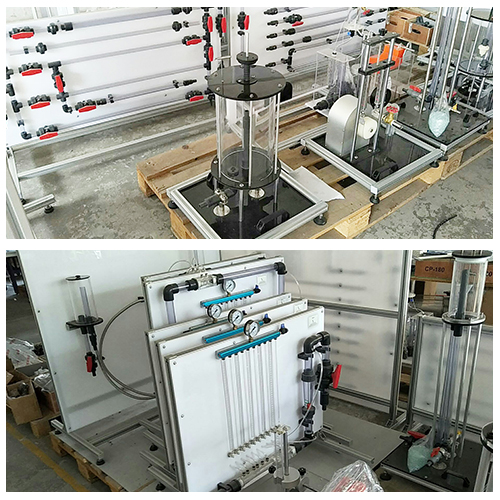

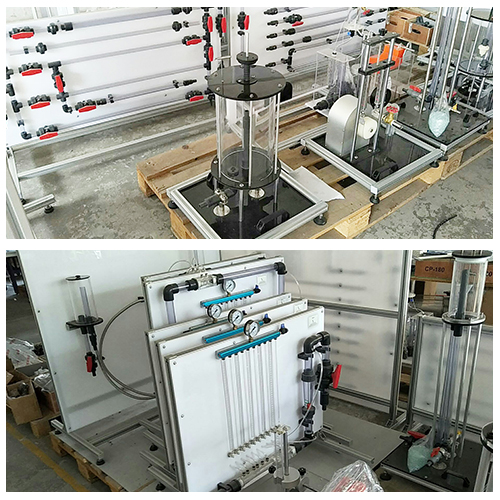

MR220507S03 Multi Process Control (including PID Controller with Software) with Computer and Backup UPS Process Control Trainer Didactic Equipment

The equipment should be able to demonstrate the followings:

• Proportional, Integral and Derivative control

• Cascade control

• Determining the dead time

• Response and characteristics of the process

• Tuning techniques of controllers

Specifications/Provisions (or equivalent)

The unit must be equipped with (or corresponding part):

• Framework: Stainless steel or anodized aluminum with enough thickness to withstand the load of equipment and/or different components of equipment

• Tank with capacity of 10 l, including heating element, digital thermostat and variablespeed stirrer

• Column with capacity of 5 litres

• Centrifugal pump

Flow rate = 2000 l/h

Head = 10 m

• Air-cooled heat exchanger, including motor, cooling fan and tachometer generator

• Electronic flow-rate transmitter including calibrated diaphragm with range of 0 to 300 l/h and 4 to 20 mA output signal

• Electronic differential-pressure transmitter with 4 to 20 mA output signal and range of 0 to 250 mm H2O

• Pneumatic control valves

• Electro-pneumatic converters, 4 to 20 mA / 0.2 to 1 bar

• Piping and valves

• Safety control

• PID controllers

• Automated unit along with software for computerized control of the equipment

• Computer

• UPS with enough backup for shutting down the unit/equipment in case of power failure

• List of spares (for 1 year)

• The unit must be supplied with all mandatory accessories for smooth operation, gases along with cylinders, installation & after-sale maintenance services, calibration kits (if any) and practices manuals.