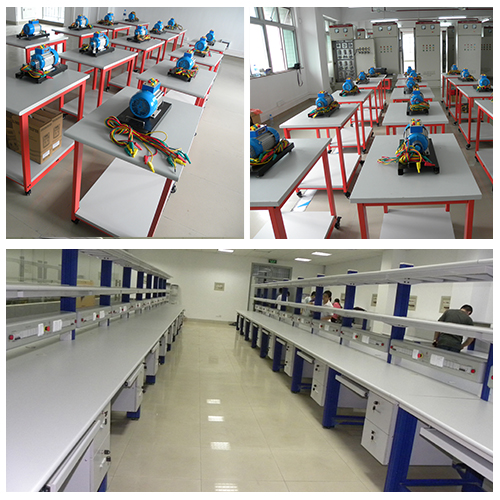

MR119M Hybrid Electro Hydraulic And Electro Pneumatic Equipment Mechatronica Training Equipment Vocational Training Equipment

1. Equipment introduction

1.1 Overview

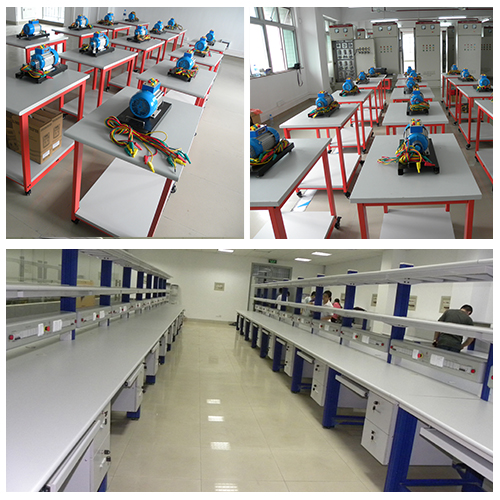

MR119M hybrid electro-hydraulic electro-pneumatic equipment adopts a double-sided structure, that is, one experimental bench provides students with a place for pneumatic and hydraulic experiments at the same time. It can conduct double-sided comprehensive pneumatic and hydraulic experiments at the same time, optimizing shared resources and improving product performance.

Through this set of practical training equipment, you can conduct pneumatic control and hydraulic control circuits and their corresponding basic application experiments. It can also be integrated with each other to conduct the following experiments: realize gas-electric control, gas-liquid control, electric-hydraulic control, and gas-electric-hydraulic integrated control.

1.2 Features

(1) This system can be used to design pneumatic and hydraulic circuits and learn pneumatic and hydraulic control technology.

(2) T-shaped slot aluminum platform enables quick connection of components.

2. Technical parameters

Total power input: three-phase AC220V

Size: 1550mm*860mm*1800mm

Weight: <282kg

Working conditions: Temperature -10℃~+40℃, relative humidity <85% (25℃)

3. Components list and detailed introduction

3.1 Hydraulic main part

No Name

1 Frame

2 Basic components (integrated tool box, hydraulic station, oil pan)

3 Universal wheel

4 Power supply hanging box

5 PLC hanging box

6 DC24 power supply hanging box

7 Emergency stop button hanging box

8 Button hanging box

9 Relay hanging box

10 Operation panel

3.2 Hydraulic components

No Name

1 Two-position four-way manual valve (transparent)

2 Three-position four-way manual valve (transparent)

3 Two-position four-way solenoid valve (single) (transparent)

4 Two-position four-way solenoid valve (double) (transparent)

5 Three-position four-way solenoid valve (double) (transparent)

6 One-way sequence valve (transparent)

7 One-way pressure reducing valve (transparent)

8 Pilot-operated check valve (transparent)

9 One-way throttle valve (transparent)

10 Throttle valve with pressure compensation (transparent)

11 Bidirectional hydraulic motor (transparent)

12 Double-acting cylinder with stroke collision block (transparent)

13 Pressure gauge (transparent)

14 Three-way valve (transparent)

15 Hydraulic auxiliary oil tank (transparent)

16 Hydraulic hose

3.3 Pneumatic main part

No Name

1 Frame

2 Basic components (integrated tool box, air pump, oil pan)

3 Universal wheel

4 Operation panel

5 Power supply hanging box

6 DC24 power supply hanging box

7 PLC hanging box

8 Relay hanging box

9 Time relay hanging box

10 Button hanging box

11 Emergency stop button hanging box

12 Buzzer hanging box (not marked in the picture)

3.4 Pneumatic components

No Name

1 Three-position five-way manual valve

2 Two-position three-way solenoid valve

3 Two-position five-way solenoid valve

4 Three-position five-way solenoid valve

5 delay valve

6 Knob button valve

7 Quick exhaust valve

8 Two-position three-way stroke valve

9 Micro Switch

10 Limit switch

11 Single port three-position valve

12 Pneumatic travel switch mechanical valve

13 One-way throttle valve

14 doublet

15 Double pressure valve

16 Pneumatic multi-pipe exhaust

17 capacitive sensor

18 Inductive sensor

19 Photoelectric Sensors

20 trachea

21 single acting cylinder

22 Double acting cylinder

23 Flat head button type three-position valve

24 Pressure transmitter with digital display

3.5 Introduction to hydraulic components

3.6 Introduction to pneumatic components

3.7 Accessories

No Name Qty

1 2mm safety connection cable (red) 20

2 2mm safety connection cable (blue) 20

3 2mm safety connection cable (black) 20

4 2mm safety connection cable (yellow) 20

5 2mm safety connection cable (green) 20

6 Insurance tube (3A) 5

7 Insurance tube (10A) 5

8 raw tape 1

9 4mm safety connection cable (yellow) 1

10 4mm safety connection cable (blue) 1

11 European plug 1

12 European power cord 2

4. Experiment list

Experiment 1 Hydraulic Station Introduction Experiment

Experiment 2 Two-position four-way manual valve operation experiment

Experiment 3 Three-position four-way manual valve operation experiment

Experiment 4 Two-position four-way solenoid valve operation experiment

Experiment 5 Three-position four-way solenoid valve operation experiment

Experiment 6 One-way pressure reducing valve operation experiment

Experiment 7 Pilot check valve (hydraulic control one-way valve) operation experiment

Experiment 8 Research on the relationship between throttle valve opening and closing and pressure difference

Experiment 9 Hydraulic motor operation experiment

Experiment 10 Delay valve operation experiment

Experiment 11 Flat head button type three-position valve operation experiment

Experiment 12 Knob button valve operation experiment

Experiment 13 Micro switch operation experiment

Experiment 14 Three-position five-way solenoid valve operation experiment