MR491E AC/DC Machines Apparatus Electrical Training Equipment Educational Equipment

1 Equipment introduction

1.1 Overview

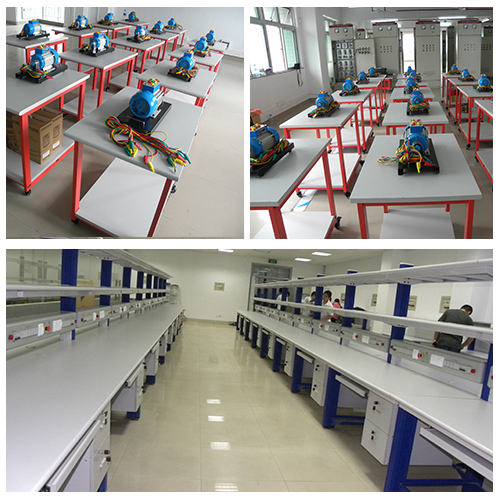

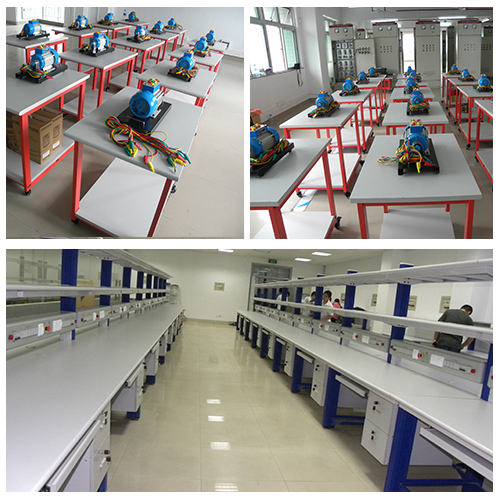

This training device includes various induction motors and industrial control components.

Through relevant experiments, students can become familiar with the characteristics of AC motors, DC motors and transformers, and master their control principles and methods.

1.2 Features

(1) The training platform adopts an aluminum profile column frame structure. There are adjustable feet at the bottom, and the height can be adjusted individually according to the ground conditions.

(2) Various types of motors are fully configured and can be used in combination.

(3) The combination of software and hardware can complete practical training content for a variety of subjects

(4) The training platform has a good safety protection system.

2 Technical parameters

Input power: three-phase five-wire 380V±10% 50Hz

Overall dimensions: 1640mmx850mmx1900mm

Overall machine capacity: <2KVA

Weight: <100kg

Ambient temperature: -10℃~+40℃

Relative humidity: <85% (25℃)

3 Product composition

3.1 Training table

3.2 Supporting modules

(1) Transformer module

(2) Torque speed transmitter, magnetic powder brake module

(3) Three-phase auto-voltage regulator module

3.3 Equipment configuration list

(1)1 safe hanging box

(2)1 inductive load hanging box

(3)1 motor protector hanging box

(4)1 resistive load hanging box

(5)1 leakage circuit breaker hanging box

(6)1 hanging box for digital display three-phase multi-function LCD instrument

(7)1 hanging box for 1K/300W sliding transmitter

(8)2 3K/50W sliding transmitter hanging boxes

(9)1 reversing switch hanging box

(10)3 AC ammeter hanging boxes

(11)2 AC voltmeter hanging boxes

(12)0-50Ω/100W starting resistor-sliding rheostat hanging box 1

(13)1 intelligent dual-channel digital display controller hanging box

(14)1 hanging box for torque and speed acquisition module

(15)1 four-pole switch hanging box

(16)1 reactive power compensation capacitor hanging box

(17)1 star-delta start switch hanging box

(18)1 brake controller hanging box

(19)2 DC ammeter hanging boxes

(20)2 DC voltmeter hanging boxes

(21)1 PWM DC speed control module hanging box

(22)1 tachometer module hanging box

(23)1 capacitive load hanging box

(24)Start the resistance hanging box

(25)Excitation power supply hanging box

(26)2 voltage transformer modules

(27)1 phase sequence check module

(28)1 phase sequence relay module

(29) Motor module

① Single-phase capacitor motor;

② Three-phase AC squirrel-cage asynchronous motor;

③ Three-phase AC excitation synchronous generator

④; Three-phase AC wound motor;

⑤ Series DC motor (generator);

⑥ Shunt DC motor ( Generator);

⑦ Compound-excited DC motor (generator);

⑧ Separately-excited DC motor (generator)

4 Experiment List

AC Devices and Equipment Experiments:

1. Single-phase two-winding transformer characteristic test: polarity test, open circuit test.

2. Transformer voltage regulation and efficiency.

3. Convert the two-winding transformer to an autotransformer.

4. Single-phase transformers operate in parallel.

5. Three-phase transformers and three-phase transformer groups.

6. Open delta or V-V connection of the transformer.

7. Scott connection or T-T connection of two single phase transformers.

8. Three-phase transformers or three-phase groups operate in parallel.

DC mechanical experiment:

1. Familiar with electromechanical energy conversion equipment.

2. Characteristics of DC shunt generator.

3. Characteristics of DC series generators.

4. Characteristics of DC compound-excited generator.

5. Characteristics of DC series motor.

AC Machinery Experiment:

1. Wound rotor induction motor. (Using three-phase power supply)

2. Squirrel cage induction motor. (Using three-phase power supply)

3. Synchronous motor.

4. DC series motor.

5. Open circuit saturation curve of alternator.

6. External characteristics of three-phase alternator.

7. Synchronous and parallel operation of three-phase alternators.