MR426E Electrical Technology Know-How Training Set Electrical Engineering Lab Equipment Technical Education Equipment

1 Product Overview

1.1 Overview

This product can be used in the training and teaching of electricians (including elementary, intermediate, and advanced electricians). The practical operation of the electrical control circuit of the motor is an indispensable skill training, and it is also the content that must be mastered by electricians at all levels. It is also issued by the Ministry of Labor. The content of the assessment and appraisal stipulated in the "Electrical Technical Grade Standard" and "Electrical Operation Certificate", the general electrician training appraisal and assessment device, the electric drag control circuit and other experiments and practical wiring and other items.

In order to cultivate students' basic skills and wiring skills in practice, the electrical technical knowledge training set greatly enriches the content of classroom practice teaching, improves the quality of practice teaching, and allows students to quickly master practical operation skills knowledge and practical wiring skills, making training teaching easier It is suitable for the teaching and skill training assessment of related majors in higher vocational schools, vocational schools, secondary vocational schools and technical schools.

It can be used to cultivate students' multi-disciplinary electrical skills, installation technology, fault analysis, and can also be used to conduct experiments, basic skills, professional skills and comprehensive skills in electrical and related professional disciplines. And can carry out subject design, electrical grade assessment, skill appraisal and so on. From general lighting circuits to closed loop automatic control can be carried out on this device. The training method is standardized and has great flexibility.

1.2 Features

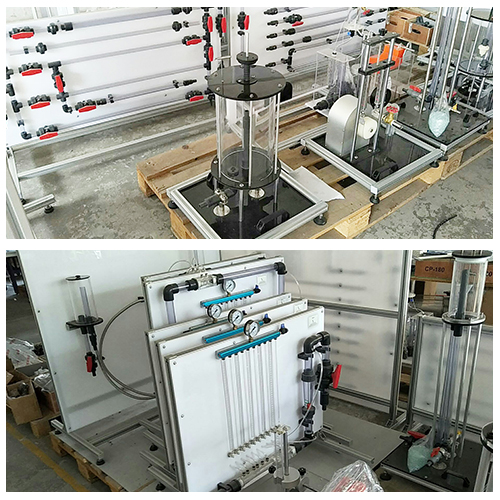

(1) Equipped with single-phase watt-hour meter, leakage circuit breaker, contactor, relay, thermal relay, travel switch, button, signal lamp, transfer switch, voltmeter, ammeter and three-phase four-wire watt-hour meter. In order to prolong the service life of the electrical appliances and reduce the consumption of materials, the contacts of each electrical appliance have been connected to the terminal blocks. Students only need to train on the terminal blocks to ensure the durability of the electrical components. The technical training cabinet is also equipped with an attached motor, through which various experiments can be performed.

(2) The motor is fully equipped and can be used in combination to complete the training content of various courses.

(3) The training platform has a good safety protection system.

2 Performance parameters

(1) Input power supply: three-phase five-wire system 380V±10% 60Hz

(2) Dimensions: 720mm×550mm×1800mm

(3) Overall capacity: <1.5KVA

(4) Weight: <150kg

(5) Working conditions: ambient temperature -10℃~+40℃, relative humidity <85% (25℃)

3 Product Composition

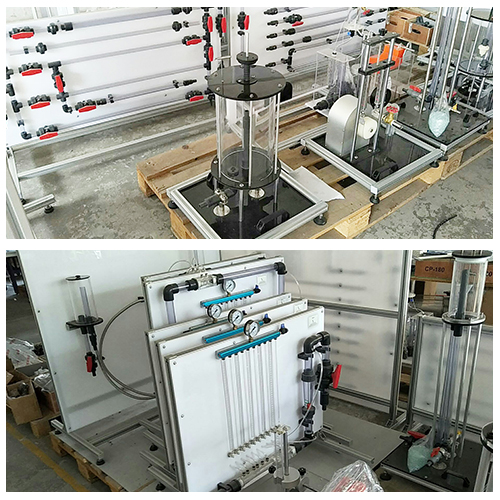

3.1 Frame

(1) Three-phase five-wire power input.

(2) Equipped with power indicator lights and safety power output terminals.

(3) Controlled by leakage circuit breaker, output three-phase power supply and single-phase power supply.

3.2 Power box part

The source box provides multiple three-phase five-wire power supplies and multiple single-phase power supplies. With overcurrent, undervoltage, short circuit, leakage protection devices. Equipped with an emergency stop switch, which can cut off the power supply in an emergency to ensure personal safety.

3.3 Supporting Devices

(1) Single-phase capacitor motor

(2) Three-phase asynchronous motor

(3) Auxiliary contact of AC contactor

(4) Safety electrical connection cable

4 Complete the training content

Experiment 1 Three-phase asynchronous motor direct starting control

Experiment 2 Three-phase asynchronous motor contactor jog control circuit

Experiment 3 Three-phase asynchronous motor contactor self-locking control circuit

Experiment 4 Three-phase asynchronous motor with thermal-magnetic protection contactor self-locking control circuit

Experiment 5 Jog and Continuous Hybrid Forward Control Circuit

Experiment 6 Manual star-delta start control circuit

Experiment 7 Automatic timing star-delta start control circuit

Experiment 8 Reversing switch forward and reverse control circuit

Experiment 9 Contactor self-locking three-phase asynchronous motor forward and reverse control

Experiment 10 Button self-locking three-phase motor contactor forward and reverse control

Experiment 11 Forward and reverse control of double self-locking three-phase asynchronous motor

Experiment 12 Three-phase asynchronous motor remote and local control

Experiment 13 Control circuit for forward and reverse jog start of three-phase asynchronous motor

Experiment 14 Workbench automatic round-trip control circuit

Experiment 15 Automatic shuttle control circuit with jog

Experiment 16 One-way motor starting control circuit

Experiment 17 Installation circuit of single-phase watt-hour meter

Experiment 18 Installation of three-phase four-wire watt-hour meter (direct type)

Experiment 19 Installation circuit of voltmeter and ammeter