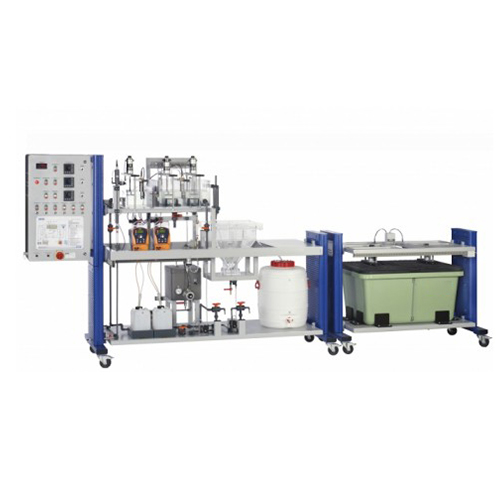

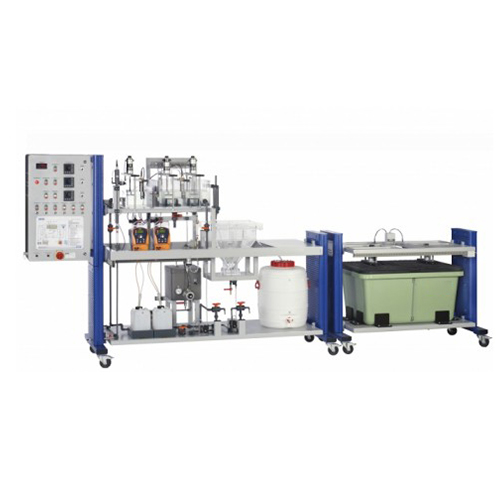

MR001W Water Purification Pilot Plant Educational Equipment Teaching Equipment Education Training Equipment

The activated sludge pilot plant consists of an oxidation reactor of a settler and of a fi nal chlorination tank, according to the traditional diagram of single-stage sewage treatment process.

Biomass is oxidized in a reactor with agitator by the air blown by a compressor. The processed liquid is sent to the settler through an overflow.

The sludges settling on settler bottom are recycled by a recirculation pump into the oxidation tank.

The water fl owing out of the settler is chlorinated and conveyed to a drain.

Process control, data acquisition and supervision are automatically carried out by a microprocessor controller and by a specific control and supervision software that enables the remote control of various operational parameters.

• Framework of AISI 304 stainless steel with castors

• Feed tank with capacity of 700 l

• Cylindrical oxidation reactor of transparent methacrylate, with capacity of 300 l, including an agitator of AISI 304 stainless steel with geared motor and air diffuser of AISI 316 sintered stainless steel

• Settler of transparent methacrylate, with capacity of 150 l

• Feed tank for hypochlorite solution, with capacity of 20 l

• Chlorination tank of transparent methacrylate, with capacity of 6 l

• Magnetic drive feed gear pump, with body of AISI 316 stainless steel, flow-rate 0 to 60 l/h

• Sludge recirculation magnetic drive gear pump, with body of AISI 316 stainless steel, fl ow rate 0 to 60 l/h

• Metering pump of sodium hypochlorite, flow rate of 0 to 1.5 l/h

• Diaphragm compressor with body of stainless steel, flow rate of 1.2 Nm³/h

• Board-type microprocessor-controlled pH-meter, with range of 2 to 12 pH and 4-20 mA output signal

• Board-type microprocessor-controlled dissolved oxygen meter, with range of 0 to 10 ppm and 4-20 mA output signal

• Flowmeter for measuring the feed flow rate of air to the reactor, with range of 0 to 1800 Nl/h

• Electronic magnetic-induction transmitter of AISI 316 stainless steel for feed fl ow rate, with range of 0 to 60 l/h and 4 to 20 mA output signal

• Board-type electronic indicator of feed flow rate with range of 0 to 60 l/h

• Electronic magnetic-induction transmitter of stainless steel AISI 316 for sludge recirculation fl ow rate with range of 0 to 60 l/h and 4 to 20 mA output signal

• Board-type electronic indicator of sludge recirculation flow rate with range of 0 to 60 l/h

• Thermoresistance Pt 100 with sheath of AISI 316 stainless steel

• Board-type electronic temperature indicator

• Switchboard IP55, complying with EC conformity mark, including plant synoptic and ELCB

• Emergency pushbutton

• Plant synoptic

• Connecting lines and valves of AISI 304 and 316 stainless steel

• Max. feed: 1 kg/day of COD (1.7 g/l for a fl ow rate of 25 l/h) Power supply: 230 Vac 50 Hz single-phase - 1 kVA (Other voltage and frequency under request) Dimensions: 2100 x 870 x 2400 mm

Weight:280kg Installation, Training and Commisisoning is required.