MR382E Didactic Station Of Foundations Of Circuits With Contact Vocational Training Equipment Smart Grid Training Equipment

I. Product overview

1.1 Overview

This training device includes slip ring motors, three-phase squirrel cage asynchronous motors, DC compound excitation motors, Darland motors, starters and other devices. Through related experiments, you can be familiar with slip ring induction motors, three-phase squirrel cage asynchronous motors and The principle of Daland electric motor and so on. Cultivate students' corresponding knowledge and skills, suitable for teaching and skill training assessment of related majors in higher vocational schools, colleges, secondary vocational schools and technical schools.

1.2 Features

(1) The training platform adopts an aluminum profile column frame structure, the measuring instrument and the training power supply are built-in and integrated installation, and the training circuit and components are combined in a hanging box. Each unit is flexible, convenient to use, and not easy to damage.

(2) The experimental circuits and devices are fully equipped and can be used in combination to complete the training content of a variety of courses.

(3) The training platform has a good safety protection system.

II. Performance parameters

(1) Input power: three-phase five-system AC220V±10%

(2) Dimensions: 1575mm×680mm×835mm

(3) The capacity of the whole machine: <1KVA

(4) Weight: <100kg

(5) Working conditions: ambient temperature -10℃~+40℃ relative humidity <85% (25℃)

III. Product composition

3.1 Power box

The power control box adopts an aluminum alloy profile panel and a closed box structure, which is connected with the lower shelf as a whole.

3.2 Training table

The training table is supported by aluminum profile columns, and the bottom universal wheels are braked, which can be moved and positioned flexibly. The desktop adopts a 25mm-thick high-density substrate, and the surface is treated with high temperature and high pressure fireproof board veneer, with a firm structure and beautiful appearance.

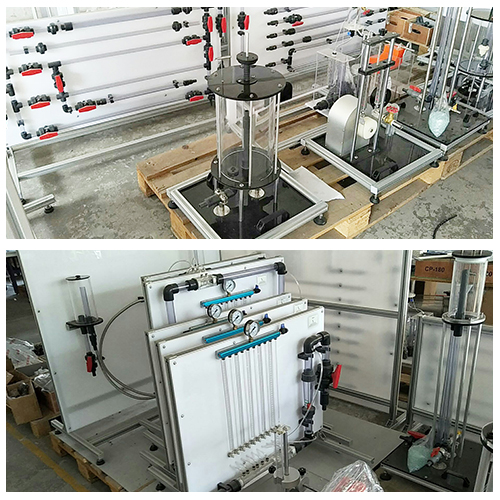

3.3 Power control panel configuration

(1) Three-phase five-wire system power input, controlled by a leakage circuit breaker, equipped with an emergency stop control button. In an emergency, press the emergency stop button and the circuit breaker will cut off the power.

(2) Equipped with DC power supply DC220V output and DC0-220V output.

(3) Equipped with power indicator light, power output socket and safety type power output terminal.

(4) Built-in AC power supply with short circuit protection function.

(5) Equipped with a torque and speed display instrument, which is used to display the torque and speed of the motor.

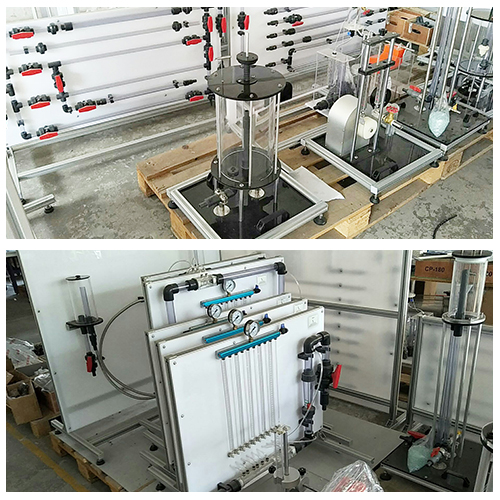

3.4 Hanging box module

This module can meet students to do a variety of different experiments. Each test module is made according to standard size. When installing, insert the upper end of the module into the upper beam aluminum profile slot, and then align the lower end of the module with the lower groove and push it down. Clip the module to the beam. The hanging box module is shown in the figure.

Schematic diagram of hanging box module

3.5 Supporting device

(1)4 AC contactor module hanging boxes

(2)1 Brake control module hanging box

(3)1 Button module hanging box

(4)1 Star triangle start switch hanging box

(5)1 three-phase motor start protector module

(6)1 Three-phase adjustable power supply

(7)1 slip ring motor starting rheostat

(8)1 Daland motor starter module

(10)1 Torque speed braking mechanism

(11)1 slip ring induction motor

(12)1 three-phase squirrel cage asynchronous motor

(13)1 DC compound motor

(14)1 Daland electric motor

(15)30 4mm safety electrical cable

(16)1 multimeter

IV. Can complete the training content

(1) AC contactor control three-phase squirrel cage motor starting training

(2) AC contactor control motor forward and reverse training

(3) Daland motor starting training

(4) Start training of DC compound excitation motor

(5) Slip ring induction motor starting training